Dyeing Silk Yarn

This is the way that I dye my silk yarns. I make no representation that this is the only way to do it, or the best way - but it gives me very consistent color across a whole skein, and allows me to control tone and depth of shade fairly well. If you are unfamiliar with dyeing and want to give it a try, there are several excellent books on the subject. Deb Menz's Color in Spinning is back in print from Interweave, and it's a goldmine of densely packed information.

Safety first. When using dyes, I always wear gloves. I wear goggles and a particulate mask when handling the dry dyes, which can be a respiratory hazard. Once they are wet in solution, they are not as dangerous. It is crucial to treat all chemicals, whether natural or synthetic, with care and respect.

These are the various pieces of equipment. I use lab glass beakers to measure my dye solutions, stainless steel bowls, kettles, and spoons, stainless steel chopsticks for stirring and lifting skeins, and a tiny gem scale to measure dye powders. The eye dropper is useful for measuring small amounts of dye, or for handling small amounts of the adjunct chemicals. It is important to have dedicated equipment for dyeing - you should not use any of the equipment for food after it's been used for dye. Goodwill is a great source for things like iced tea spoons, kettles, and glassware. Never use cast iron, aluminum, or any other reactive metal - it can affect your results a lot, and in some cases also damage the utensils.

These are the adjunct chemicals that I use for dyeing. Citric acid powder changes the pH of the dye bath, making it mildly acidic, which causes the color to strike on the yarn. The three bottles across the front are from Dharma Trading Company: Milsoft, Synthrapol, and Calsolene Oil. Milsoft is a fabric softening rinse which I use after dyeing to help restore the soft silky hand of the skeins. Synthrapol and Calsolene Oil help to level and disperse the dye, so that it takes evenly across the skein instead of making hot spots. Synthrapol is also used to rinse off excess dye.

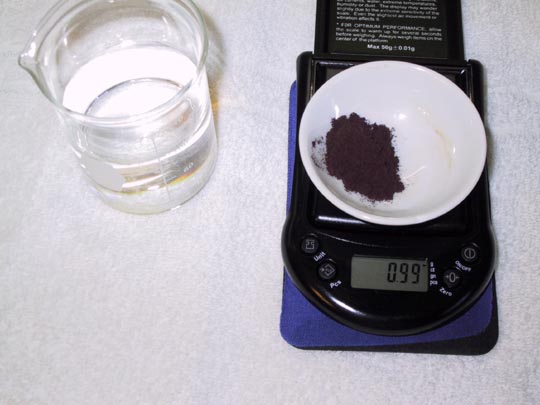

This is acid dye powder. Acid dyes are comparatively easy to use and easy to get hold of - Dharma Trading and Pro Chemical both make excellent lines of colors. Acid dye is washfast and permanent. I mentioned wearing gloves, didn't I?

I begin by making a 1% solution with the dye. I measure one gram (or .99 grams - it's really tricky to get a hundredth of a gram to go where you want it to!) on the scale. This is put into 100 ml. of very hot water - just about 3.5 ounces. Some dyes dissolve easier than others; if the dye is tricky to dissolve, it is best to put in just a small portion of the water, and stir to make a paste, then add the remainder of the water.

This is the 1% dye solution. I also add just a couple of drops of the Calsolene Oil, which helps the dye molecules blend with the water. If you don't have Calsolene, a little bit of Synthrapol will do. Once the dye solution is mixed up, set it aside.

This is a skein of 2/30's silk. It has been tied at the factory; if you make your own skein, use at least three cross-ties, and make sure to lace the ties through the skein several times. This helps prevent tangling, and makes the skein easier to unwind. The bowl behind the skein contains a couple quarts of water, a teaspoon or so of citric acid, and a little dollop of Synthrapol. This solution is used to wet out the silk. Gently wet the silk in the solution and let it soak there for about 30 minutes; this helps make sure that the silk fibers are wet all the way through and ready to receive the dye.

If you have a very small amount, like this five-yard skein of embroidery silk, you don't need to tie up the skein. I keep a long-handled teaspoon through the center, which keeps the skein open and prevents tangling.

This is the bowl with the big skein, plus four small skeins of embroidery silk. Note that each one has its own spoon sticking through the middle of the skein.

Mix up the dye bath. This bath has about 30 mls of the dye solution, plus a tablespoon of citric acid powder, a half-teaspoon of Calsolene Oil, and a teaspoon of Synthrapol. The amount of water is sufficient to allow the skeins to float freely. Because the dyes will react chemically with the yarn, the amount of water doesn't need to be precise - it just needs to give enverything plenty of room. The amounts of dye are based on the weight of the yarns. This is about a 1/3 solution - one ounce of dye for 3 ounces of yarn. I'm the first to admit, I'm not terribly consistent with that measurement - in order to get perfectly repeatable results, you need to make accurate measurements and keep scrupulous notes. I tend to be more organic, and add color until it feels right. This color is a blend of Jacquard colors Cherry Red and Salmon - I wanted a vermillion color, and the salmon knocks out a little bit of the blue color in the Cherry.

This is how I start putting the skeins into the dye bath. The embroidery skeins go into a little kettle, while the 2/30's goes into a large stock pot. Begin by putting the skein (with its spoon) partway into the kettle, then rotating the skein and putting the undyed portion in. This makes sure that the skein gets an even start. The motion is up and down, kind of like dunking a teabag.

Here, you can see where I've turned the skeins, ready for the other end to get dunked.

Once the skeins are fully dunked, lower them into the kettle with the spoons in place, and let them simmer for 30 minutes. This allows them to absorb the dye from the dyebath, as well as helping the dye set on the fabric.

Back to the big skein, which is all dunked and ready to start simmering. The dye bath should never boil, but should stay quite hot. The lowest simmer setting is perfect. The dye bath should ideally be about 185'F.

After about 10 minutes, you can see that the dye bath is becoming much more clear. This process is called exhausting. The dye leaves the water and goes into the silk.

After the 30 minutes are up, the dye bath is nearly clear. There is still a tinge of pink to it, but it's done dyeing. It's time to rinse!

Begin with water with a little bit of Synthrapol (about 1/2 teaspoon) and a tablespoon or so of citric acid, and rinse until no more color comes off. Then switch to clear water, and rinse until the suds stop.

At the end, there should be really clear water with no suds. After this, I usually use a rinse with a tablespoon of Milsoft, to give the silk a nice soft hand.

These are the dyed skeins after they have been rinsed, wrung out tightly, and partially dried.

And here's the finished red silk.