Degumming

Degumming is the process of removing the sericin, or silk gum, from silk. Removing the gum improves the sheen, color, hand, and texture of the silk. Because the gum can serve as a protective layer, it is typically left on the silk until it is ready to dye. In some cases, the fabric is woven to completion, and then degummed, to protect the yarn from abrasion on the loom.

Note: most commercial silk yarns are sold fully degummed, but some dyers still prefer to degum it again to make sure before dyeing.

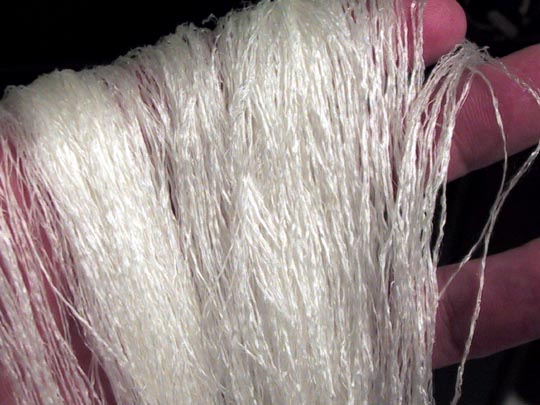

This is 8-filament raw silk which has been lightly twisted using a spinning wheel, and formed into a skein.

Here, you can see the wiry texture of the filaments, and also one of the four cross-ties. I use four cotton cross-ties on each skein, lacing them three or four times through the body of the skein. I keep all the knots on one side of the skein reel, so that I can re-orient the skein later on. I also use a cotton thread of a different color to mark the end where the skein is tied together, so that I can find it later!

At this point, the skein, including the cotton ties, weighs 24.93 grams - about 2/3 of an ounce.

The degumming solution is made of two chemicals: an alkaline and a surfactant. The alkaline is washing soda, or sodium carbonate, also known as soda ash. The surfactant is Orvus paste, which is pure sodium lauryl sulfate, the detergent that gives lather to products from shampoo to toothpaste. You can substitute other surfactants, but try to avoid dish or laundry detergents that have enzymes, which can harm the silk.

SAFETY NOTE: The chemicals used in this process are about as dangerous as laundry detergent. I tend to think of that as being relatively safe - but read the label on your box of TIDE, and you'll find out otherwise! Take appropriate cautions; you may wish to use eye protection, gloves, and a mask. The main caution listed on the packaging of the chemicals, is to avoid getting it in your eyes.

The recipe:

1/4 cup washing soda

1/4 cup Orvus paste

enough water to make one gallon

I like to mix the solution in an empty gallon water jug. Make sure to label it first so you don't forget what's in it later! The solution does not go bad, but it will settle; if you store it and use it again later, make sure to shake it. Put the washing soda into the jug with a funnel. Follow it with some hot water - that's important, because otherwise it can form a clump in the bottom of the jug. Shake the jug around to dissolve the washing soda.

The Orvus paste will change consistency depending on the temperature. When it's warm, it's soft and oozy like honey. Today it's cool, so it's solid, about the consistency of shortening.

I scoop it up, level it off, and put it in the funnel.

It takes a litte more warm water to make the Orvus paste soften up and go down into the jug.

Poking it helps. This is one of my favorite poking tools - a stainless steel chopstick.

Pour enough water in to make the gallon jug pretty much full. Sometimes the Orvus will will suds up, making it difficult to fill the jug completely. Once it's full of water, close the jug and shake it until it's stirred evenly and everything is dissolved.

Pour the solution into a kettle big enough to float the amount of silk you're going to degum. DO NOT PUT THE SILK IN YET. I'm using a big stock pot, because this is a fairly large skein. Bring the solution to a boil, and then reduce the heat so that it remains hot, but without any bubbling.

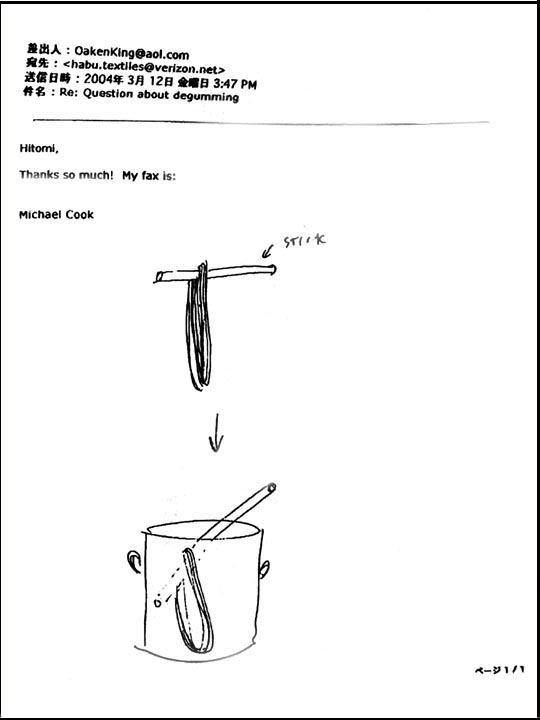

It's hard to see here, but the spoon is going through the middle of the skein. This is a trick I learned from the nice folks at Habu Textiles - they use a stick. When Hitomi kept trying to explain to me by email how to use the stick, I just didn't get it - she finally sent me a simple but very helpful fax.

It's amazing how much difference it makes to see something like this in a picture. Of course.

This is helpful with all kinds of dye work, not just with silk!

In order to get the silk thoroughly wet, I dunk it up and down a few times. The sericin immediately starts to turn slimy, and the silk where it's under the water looks like a loose cloud.

Let the silk simmer for 30 minutes or so, turning gently at least once, preferably twice. Leave the spoon in the kettle, going through the skein, the whole time; it makes it MUCH easier to pick the skein up, and it helps avoid tangling.

Once the skein is fully degummed, begin rinsing in warm water. Use the spoon, and dip the skein up and down to rinse it. Use a bowl or sink full of clear water; do not run it under the tap as it can mat up or tangle the silk. After the silk stops making suds when you rinse it, make a rinse in a mild citric acid solution - about a tablespoon of citric acid to a gallon of water. This helps to neutralize any residual alkaline from the degumming.

I like to use a final rinse with MilSoft; this helps make the silk softer and

less likely to snag on my hands during later processing.

It seems counter-intuitive, but the silk benefits from vigorous wringing. I had to drop one side of this to take the photo. Often, two sticks are used, and turned in the ends of the skein to wring it tightly. It's amazing how much of the water will come out this way!

This is the still-damp silk. You can see the change in the texture already, but the real changes will show more once it's dry.

One of the most significant differences, is that the skein loses a lot of weight! After degumming, the skein weighs 19.45 grams, which means that it's lost 5.48 grams, or about 22% of its original weight. Typical silks will lose between 15% and 25%.

I'm making little skeins of this flat silk, so that I can dye them in various shades for an embroidery project. I use the open end of an itomaki to make the skeins.

The strands are fairly soft already from the degumming, but they still have a little bit of crimp from being simmered and dried. In order to smooth it out and make it truly flat, I take the skein and stroke it along my thumbnail. I pile it up on a napkin to keep it out of trouble.

It looks like it would make a tangled mess, but as long as it's not stirred or pulled out of order, this pile of thread will come back up neatly when I'm ready to wind it into a skein.

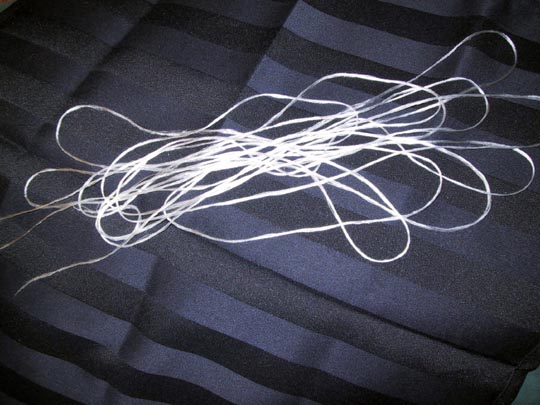

Now, the sheen and openness of the flat silk really shows. These are approximately five-yard skeins.

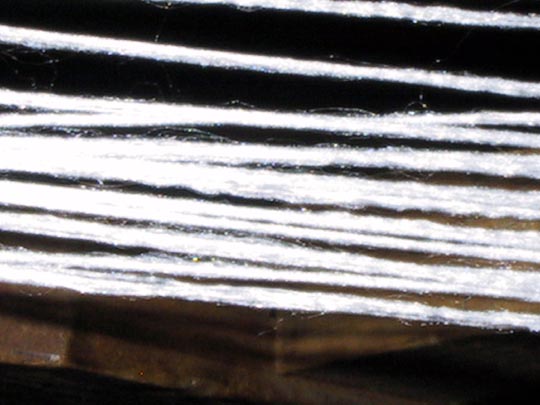

Here, you can really see the texture and shine of the silk. This silk is made from 8 reeled filaments, each of which has between 15 and 25 cocoon threads - so this finished flat silk is about 160 cocoon baves in weight.

If the silk is going to be worked white, it's ready to go. Otherwise, the next step is the dye vat!