How I Throw

A friend of mine recently asked me how I go about throwing (twisting) my filament silk yarns. Throwing is needed to turn the totally-flat raw silk into tram and organzine; it’s a little like spinning, and a little like plying, but it’s really its own thing.

To start with, I wind all the filament onto silk-throwing spools. These special spools have fat cores and gutta-percha ends, which won’t snag on the filament. They sit flat on their butts, so that you can pull upward and unwind the silk without putting pressure on it and causing it to break. These are old spools from a silk factory, used on the throwing machines.

I put the spools flat on their butts on the floor. I often use a shoe-box just to keep them conveniently corralled; it makes them easier to put away when I’m done, and keeps the cat from knocking them over. One thread comes off of each spool, straight up to the ring which is affixed to the table with a clip.

The ring, the clip. I’ve got two rings on it this time, which sometimes helps even out the tension if there’s a rough spot. The large black ring is an onyx finger ring. The small gray ring is a metal-oxide fishing line guide. The clip is a chip-clip from the hardware store.

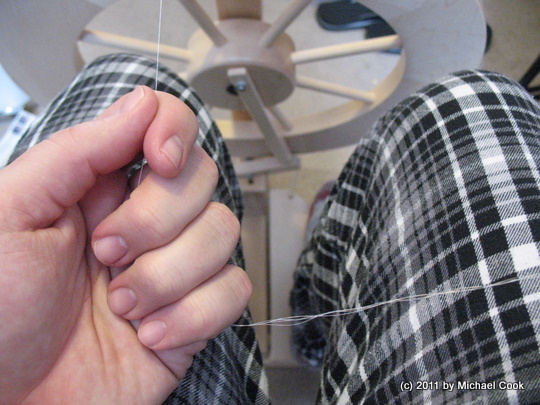

My left hand sits on my left thigh, stationary. There’s a tiny adjustment of the grip as the filament slips through it. As the right hand is moving to the right, the left hand resists just enough to stop the right hand from pulling the silk out of it; as the right hand moves back to the left, it allows the silk to slide through and to the wheel. It takes more tension than you’d think on the wheel, to get this stuff wound on without kinks. The silk that I’m working on now is low-twist, high-shine organzine; it has about 7.5 twists per inch. For sewing thread, the number is more like 20.

The filament in this photo really should be more horizontal, like the shot before; I had to let go with my left hand to shoot the picture. My right hand sits on my right thigh, rocking back and forth, pivoting on the wrist. As it moves from left to right, it’s sliding along the silk to get a new four-inch length. As it moves back from right to left, eventually bumping the left hand, it is gripping the silk as the left hand allows the new length to pass forward to the wheel. It works like the stitch regulator on a sewing machine. To increase the amount of twist, I either adjust the ratio on the wheel, or I adjust the distance between my two hands. If the right hand is closer to the left, I get a smaller bite of silk each time. If it’s further away, I get more silk each time. I time the motions so that they coincide with the feet on the pedals; this way I know that right-left advances four inches of silk, which equates to 30 revolutions of the flyer (for this particular silk) – thus adding 7.5 twists per inch. If I’m doing high-twist, it’s typically two pairs of treadles (left-right, left-right) to one hand motion. I find it’s a lot easier to measure roughly four inches or so, and the scope of error is a lot less. If you’re aiming for an inch, and you end up with an inch and a half, you’re off by half… if you are aiming for four inches, and you’re off half an inch, you’re only off about twelve percent.

great explanation- thanks. now to see if i can approximate it in some small way to begin..